CHLOROPAC® - MGPS

Efficient Chloropac® Electrochlorination System

The Chloropac® system produces a diluted sodium hypochlorite solution for direct water circuit injection, combating marine growth effectively. Our cutting-edge Chloropac® MGPS technology, featuring various cell designs, coupled with extensive expertise in anode and system development, has liberated thousands of customers worldwide from harsh chemical costs and hazards associated with other technologies. Chloropac utilizes CTE technology, optimizing chlorine generation with increased cell capacity, making systems up to 76% smaller and lighter than previous models. This ensures ease of installation and saves on real estate. Moreover, our patented self-cleaning technology eliminates the need for costly acid washing, allowing uninterrupted operations without biofouling concerns.Why Choose Chloropac® MGPS Systems?

- Over 40 years of operational experience with 3,000+ worldwide installations

- Configured standard systems with output capacities ranging from 50 grams/hr to 500 Kg/hr+

- Compact, space-saving, and lightweight designs

- Globally accessible service staff and spare parts, available 24/7

- Electrochlorination services covering maintenance, retrofitting or replacement

Applications of Chloropac® MGPS Systems

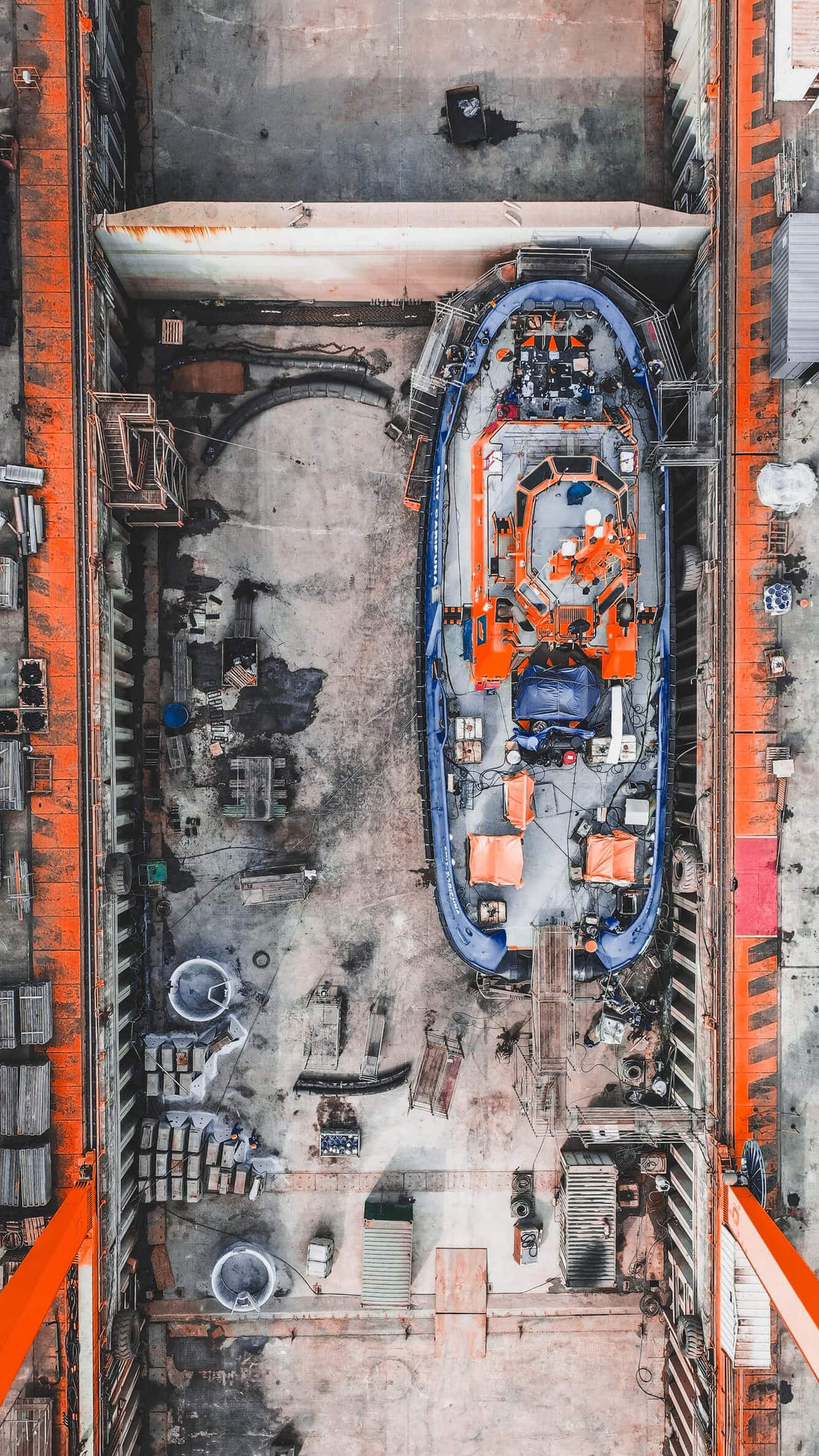

- Marine: Ships, vessels, tankers, naval fleets, supply boats, container and cruise ships, cargo, gas carriers

- Offshore structures: Fixed platforms, FPSO, FLNG, Gravity bas structures, Semi-submersible, Drill ship, wind farms

- Land-based: Power, petrochemical, industrial

Understanding Electrochlorination

The Evoqua CTE cell forms the core of the Chloropac® unit, utilizing C.T.E. technology for reliable electrochlorination. Developed by Electrocatalytic engineers, this technology efficiently converts sodium chloride into sodium hypochlorite, the active ingredient for anti-fouling. The concentric electrode design ensures uniform electrolyte flow, preventing calcareous deposits and optimizing system performance.

Enhanced Electrolytic Cell Assembly

The C.T.E. electrolytic cell assembly comprises two concentric titanium tubes through which saltwater (seawater) flows. By applying an electric current to the saltwater, Chloropac® converts sodium chloride into sodium hypochlorite, the active ingredient needed for anti-fouling.Advantages of Concentric Electrode Design

The development of the concentric electrode design resulted in a flow cell constructed of concentric cylindrical anode and cathode assemblies, one inside the other. This C.T.E. design effectively addresses deficiencies in previous plate or mesh designs. Electrolyte flow is horizontally forced in the annular space between the concentric cylinders. The flow of electrolyte is uniformly distributed from the inlet to the outlet connections, covering the concentric anode and cathode surfaces evenly. The absence of corners eliminates low flow/velocity areas where calcareous deposits of calcium and magnesium could precipitate on the electrodes or accumulate.Contact Us for More Information

If you have any questions or require spare parts for your Evoqua system. Contact us.

Operational Benefits and Flexibility

The MARINE Mk4M system offers precise dosing, ranging from 0.2 to 0.5 ppm chlorine, ensuring stable performance under varying conditions, including temperature (10-30°C) and salinity (14-19g/l). Designed for flexibility, it seamlessly integrates with vessel-specific designs, using efficient Mk4M cells and the Power Supply Unit (PSU). Installation is straightforward, and an optional service exchange for the cells enables faster maintenance turnaround. Mk4M-SB Retro Kit

Additionally, existing Chloropac® electrolysers can be easily upgraded to Mk4M cells with a Retro-Fit Kit, extending the life of current equipment without significant capital expenditure. This retrofit replaces MK2M cells with Mk4M cells, which continue producing sodium hypochlorite (NaOCI) and hydrogen (H2) through seawater electrolysis. Sodium hypochlorite, a mild bleaching agent, effectively prevents marine growth, safeguarding seawater systems from fouling and equipment damage.

Installation and Support

The Retro-Fit Kits can be installed either by EWT technicians or qualified engineers provided by the operator. If there is any uncertainty regarding installation, operators can consult the EWT Spares and Service team for expert support.

The MARINE Mk4M system offers reliable, long-term protection against marine growth while reducing maintenance needs, providing a cost-effective solution for ship operators.

Contact Us for More Information

If you have any questions or require spare parts for your Evoqua system.

Typical Chloropac® System Shipboard Installation

The MGPS Mk2M Chloropac® sodium hypochlorite generating system prevents marine growth in seawater piping, heat exchangers, sea chests, and coolers. Ship owners and operators prefer the MGPS Mk2M system, with thousands of installations worldwide. Continuous low-level hypochlorination proves more effective than other marine growth prevention methods. Chloropac MGPS has earned trust in the marine market for over 40 years.

The MGPS Mk2M Process

A small amount of seawater, 5.7m³/hr (25 GPM), constantly pressurized, passes at high velocity through MGPS Mk2M electrolytic cells, converting part of the salt to sodium hypochlorite. This solution returns to the sea chest, mixing with incoming seawater. The cooling water now contains a trace residual sufficient to prevent marine organism growth, keeping all circuits—from intake to discharge—free from fouling. The system can interconnect with seawater circulating pumps to automatically adjust sodium hypochlorite output to suit on-board flow rates.

Comparison MGPS Mk2M to Other Methods

Effective Dosage |

||

|

The Chloropac electrochlorination system effectively controls both micro and macro fouling organisms by low continuous dose of 0.5 ppm or less. Additionally, it ensures efficient marine growth prevention

|

In contrast, copper ion-type systems claim a dose rate of 1 ppb suffices for all marine growth. However, a dose rate of ~20 ppb is actually needed to control macro fouling. Additionally, continuous dissolution of copper and aluminum does not effectively combat micro fouling. | |

Cell Longevity and Maintenance Costs |

||

| The Chloropac system uses platinum-on-titanium electrolytic cells (anodes) to produce sodium hypochlorite from seawater. These cells are warranted for five years, but typically last around seven years. | Conversely, copper-based systems use “sacrificial anodes” that dissolve quickly, requiring replacement every 12-24 months at a high cost. Therefore, ongoing consumable and maintenance costs are lower with the Chloropac system. | |

Control and Environmental Impact |

||

| Chloropac system controllers can be adjusted manually or automatically to regulate hypochlorite production based on demand, allowing for zero or near-zero residual overboard discharge. | On the other hand, copper anodes dissolve continuously, discharging copper overboard and adding heavy metal pollutants to the ocean. | |

Chemical Handling and Safety |

||

| The Chloropac system produces sodium hypochlorite using only ambient seawater, eliminating the need to store biocides or precursor chemicals on board. All produced sodium hypochlorite is directly injected into the sea chests, simplifying purchasing, storage, handling, and chemical logistics. | In contrast, chemical injection systems require the storage and handling of highly corrosive and toxic chemicals, creating additional storage and safety hazards on board. | |

Conclusion

In conclusion, the Chloropac system not only provides superior control but also offers lower maintenance costs and reduced environmental impact. Furthermore, it simplifies chemical handling compared to alternative methods of marine growth prevention.

Contact Us for More Information

If you have any questions or require spare parts for your Evoqua system.

SPARE PARTS AVAILABLE FROM STOCK:

Evoqua PN |

DWG PN |

VV PN |

Description |

| W3T344631 | 4-10176 | 12997 | Cell Assembly MK2M |

| W2T624713 | 5/0849 | 10118 | Spacer pips |

| W3T290804 | 5/1000 | 11525 | Cell Anode MK2M |

| W2T624757 | 5/1001 | 11526 | Cell Cathode MK2M |

| W3T331066 | 5/1002 | 11527 | Cell Bi-polar MK2M |

| W2T624759 | 5/1003 | 11602 | Union body MK2M |

| W2T624760 | 5/1004 | 11599 | Union nut MK2M |

| W2T624761 | 5/1005 | 10122 | Split collar MK2M |

| W2T625195 | 5/1005 | 10112 | O-ring MK2M |

| W2T624762 | 5/1007 | 10123 | End cone MK2M |

| W2T624763 | 5/1008 | 11511 | Titanium pin MK2M |

| W2T624764 | 5/1009 | 10128 | Locating sleeve MK2M |

| W2T624765 | 5/1010 | 11507 | Union end MK2M |

| W2T624788 | 5/1041 | 11581 | Inner cell spacer MK2M |

| 12624 | Flow indicator DN25 | ||

| 12625 | Flow indicator DN40 |

STANDARD VALVES:

Evoqua PN |

DWG PN |

Spec PN |

Description |

| W2T630794 | 6D-16511 | 6S-13913/3 | Shipside valve DN25 ANSI 150 |

| W2T630795 | 6D-16511 | 6S-13913/4 | Shipside valve DN40 ANSI 150 |

| W2T850076 | 6D-16511 | 6S-13913/5 | Shipside valve DN50 ANSI 150 |

| W2T630801 | 6D-16768 | 6S-13929/3 | Shipside valve DN25 EN1092 |

| W2T630802 | 6D-16768 | 6S-13929/4 | Shipside valve DN40 EN1092 |

| W2T630803 | 6D-16768 | 6S-13929/5 | Shipside valve DN50 EN1092 |

| W2T631206 | 6D-19764 | 6S-30766/2 | Shipside valve DN25 JIS 10K |

| W2T631207 | 6D-19764 | 6S-30766/3 | Shipside valve DN40 JIS 10K |

| W2T631208 | 6D-19764 | 6S-30766/4 | Shipside valve DN50 JIS 10K |

| W2T625162 | 6D-17405 | 6S-13914/2 | Check Valve DN25 ANSI 150 |

| W2T625163 | 6D-17405 | 6S-13914/3 | Check Valve DN40 ANSI 150 |

| W2T802376 | 6D-17405 | 6S-13914/4 | Check Valve DN50 ANSI 150 |

| W2T630806 | 4-24357 | 6S-13930/2 | Check Valve DN25 EN1092 |

| W2T630807 | 4-24357 | 6S-13930/3 | Check Valve DN40 EN1092 |

| W2T630808 | 4-24357 | 6S-13930/4 | Check Valve DN50 EN1092 |

| W2T631117 | 6D-17750 | 6S-30629/2 | Check Valve DN25 JIS 10K |

| W2T631118 | 6D-17750 | 6S-30629/3 | Check Valve DN40 JIS 10K |

| W2T631119 | 6D-17750 | 6S-30629/4 | Check Valve DN50 JIS 10K |

| W2T821954 | 6D-19949 | 6S-32995/2 | Diaphragm Valve DN25 ANSI 150 |

| W2T821955 | 6D-19949 | 6S-32995/3 | Diaphragm Valve DN40 ANSI 150 |

| W2T821956 | 6D-19949 | 6S-32995/4 | Diaphragm Valve DN50 ANSI 150 |

| W2T821958 | 6D-19949 | 6S-32995/6 | Diaphragm Valve DN25 EN1092 |

| W2T821959 | 6D-19949 | 6S-32995/7 | Diaphragm Valve DN40 EN1092 |

| W2T821960 | 6D-19949 | 6S-32995/8 | Diaphragm Valve DN50 EN1092 |

| W2T625176 | 4-21329 | 6S-13536/2 | Diaphragm Valve DN25 EN1092 |

| W2T625584 | 4-21329 | 6S-13536/3 | Diaphragm Valve DN40 EN1092 |

| W2T630722 | 4-21329 | 6S-13536/4 | Diaphragm Valve DN50 EN1092 |

| W2T630811 | 6D-19757 | 6S-13939/1 | Diaphragm Valve DN25 JIS 10K |

| W2T630812 | 6D-19757 | 6S-13939/2 | Diaphragm Valve DN40 JIS 10K |

| W2T630813 | 6D-19757 | 6S-13939/3 | Diaphragm Valve DN50 JIS 10K |

Send your inquiry to info@venteville.com

Chloropac® MGPS MARINE Mk4M: Enhanced Flexibility and Efficiency

The new Chloropac® MARINE Mk4M system offers advanced marine growth prevention with improved flexibility, operational stability, and increased uptime. With over 40 years of proven reliability in the marine market, the Chloropac® MGPS features industry-leading self-cleaning cells, now further enhanced with the MKIV design. Hundreds of installations worldwide demonstrate the system’s ability to provide significant operational cost savings over the lifetime of vessels.

Key Benefits of Chloropac® MARINE Mk4M

The system offers adaptable dosing levels, ranging from 0.2 to 0.5 ppm chlorine, ensuring stability across varying temperatures (10-30°C) and salinity levels (14-19 g/l). This flexibility guarantees reliable performance even in fluctuating marine environments. Moreover, the inclusion of efficient Mk4M cells and a streamlined Power Supply Unit (PSU) makes the installation process straightforward and hassle-free.

To further improve operational efficiency, the system allows for an optional service exchange of cells, enabling faster turnaround times for maintenance. Additionally, existing Chloropac® electrolysers can be upgraded to Mk4M cells, extending equipment lifespan without major capital expenditure.

The Chloropac® MARINE Mk4M continues to lead the industry, delivering efficient, reliable marine growth prevention with reduced maintenance and enhanced operational stability.

Contact Us for More Information

If you have any questions or require spare parts for your Evoqua system.

System Features

- Low Pressure Drop through the electrolyser, ensuring minimal impact on system performance.

- Only 4 Cells per Electrolyser to cover the full range, simplifying system design.

- Clear Covers for easy visual inspection without removing the covers.

- Low Cell Maintenance with no O-rings required, reducing upkeep efforts.

- Quick and Easy Cell Replacement, minimizing downtime.

- Scalable Output: Additional power slices can be added to the SMPSU, allowing future system upgrades.

- Self-Regulating Output: The system automatically adjusts to varying seawater conditions (10°C – 35°C at 19 g/l salinity), ensuring consistent performance.

Chloropac® System: Effective Marine Growth Prevention for Shipboard Installations

The Chloropac® MLF system (Range SB50 – SB200) is a proven solution for preventing marine growth in seawater piping, heat exchangers, sea chests, and coolers. Ship owners and operators worldwide prefer this system, with thousands of installations already in place. Continuous low-level hypochlorination has shown to be more effective than other marine growth prevention methods, offering over 40 years of reliable service in the marine industry.

How the Chloropac® MLF System Works

The process begins by diverting a small volume of seawater—about 2m³/hr (or 9 GPM)—from a pressurized seawater line. This water flows through electrolytic cells at high velocity, where a portion of the salt is converted into sodium hypochlorite. This solution is then directed back to the sea chest, where it mixes with incoming seawater.

As a result, the cooling water contains a trace level of sodium hypochlorite, enough to prevent marine organisms from attaching and growing in the system. This method ensures all circuits, from intake to discharge, remain free from fouling. Additionally, the system can automatically adjust the sodium hypochlorite output based on the flow rate, ensuring optimal efficiency.

With its proven track record, the Chloropac® system continues to deliver effective, long-term marine growth prevention, minimizing maintenance costs and improving operational efficiency.

Comparison Chloropac® MLF system to Other Methods

Effective Dosage |

||

|

The Chloropac electrochlorination system effectively controls both micro and macro fouling organisms by low continuous dose of 0.5 ppm or less. Additionally, it ensures efficient marine growth prevention

|

In contrast, copper ion-type systems claim a dose rate of 1 ppb suffices for all marine growth. However, a dose rate of ~20 ppb is actually needed to control macro fouling. Additionally, continuous dissolution of copper and aluminum does not effectively combat micro fouling. | |

Cell Longevity and Maintenance Costs |

||

| The Chloropac system uses platinum-on-titanium electrolytic cells (anodes) to produce sodium hypochlorite from seawater. These cells are warranted for five years, but typically last around seven years. | Conversely, copper-based systems use “sacrificial anodes” that dissolve quickly, requiring replacement every 12-24 months at a high cost. Therefore, ongoing consumable and maintenance costs are lower with the Chloropac system. | |

Control and Environmental Impact |

||

| Chloropac system controllers can be adjusted manually or automatically to regulate hypochlorite production based on demand, allowing for zero or near-zero residual overboard discharge. | On the other hand, copper anodes dissolve continuously, discharging copper overboard and adding heavy metal pollutants to the ocean. | |

Chemical Handling and Safety |

||

| The Chloropac system produces sodium hypochlorite using only ambient seawater, eliminating the need to store biocides or precursor chemicals on board. All produced sodium hypochlorite is directly injected into the sea chests, simplifying purchasing, storage, handling, and chemical logistics. | In contrast, chemical injection systems require the storage and handling of highly corrosive and toxic chemicals, creating additional storage and safety hazards on board. | |

Contact Us for More Information

If you have any questions or require spare parts for your Evoqua system.

SPARE PARTS AVAILABLE FROM STOCK:

Evoqua PN |

DWG PN |

SPEC PN |

Description |

| W3T290525 | 5/1035 | 12047 | MLF 50 Cell Assembly |

| W3T290795 | 5/0988 | 11563 | Cathode MLF 50 |

| W3T290794 | 5/0987 | 10106 | Anode MLF 50 |

| W3T290796 | 5/0989 | 11562 | Inner bi polar MLF 50 |

| W3T290526 | 5/1036 | 11504 | MLF 100 Cell Assembly |

| W3T290797 | 5/0990 | 11646 | Cathode MLF 100 |

| W3T290798 | 5/0991 | 15016 | Anode MLF 100 |

| W3T290799 | 5/0992 | 11648 | Inner bi polar MLF 100 |

| W2T624744 | 5/0974 | 10115 | Union MLF |

| W2T624745 | 5/0975 | 11556 | Union nut MLF |

| W3T290793 | 5/0976 | 11552 | Split collar MLF |

| W2T625196 | 5/0977 | 10116 | O-ring MLF |

| W2T624748 | 5/0978 | 11551 | Inner spacer MLF |

| W2T624749 | 5/0980 | 11639 | Sleeve MLF |

| W2T624750 | 5/0981 | 11641 | Titanium pin MLF |

| W2T624751 | 5/0982 | 10119 | Spacer pip MLF |

| 12624 | Flow indicator DN25 | ||

| 12625 | Flow indicator DN40 |

STANDARD VALVES:

Evoqua PN |

DWG PN |

SPEC PN |

Description |

| W2T630794 | 6D-16511 | 6S-13913/3 | Shipside valve DN25 ANSI 150 |

| W2T630795 | 6D-16511 | 6S-13913/4 | Shipside valve DN40 ANSI 150 |

| W2T630800 | 6D-16768 | 6S-13929/1 | Shipside valve DN15 EN 1092 |

| W2T630801 | 6D-16768 | 6S-13929/3 | Shipside valve DN25 EN 1092 |

| W2T630802 | 6D-16768 | 6S-13929/4 | Shipside valve DN40 EN 1092 |

| W2T631206 | 6D-19764 | 6S-30766/2 | Shipside valve DN25 JIS 10K |

| W2T631207 | 6D-19764 | 6S-30766/3 | Shipside valve DN40 JIS 10K |

| W2T630797 | 6D-17405 | 6S-13914/1 | Check Valve DN15 ANSI 150 |

| W2T625162 | 6D-17405 | 6S-13914/2 | Check Valve DN25 ANSI 150 |

| W2T625163 | 6D-17405 | 6S-13914/3 | Check Valve DN40 ANSI 150 |

| W2T630805 | 4-24357 | 6S-13930/1 | Check Valve DN15 EN 1092 |

| W2T630806 | 4-24357 | 6S-13930/2 | Check Valve DN25 EN 1092 |

| W2T630807 | 4-24357 | 6S-13930/3 | Check Valve DN40 EN 1092 |

| W2T631116 | 6D-17750 | 6S-30629/1 | Check Valve DN15 JIS 10K |

| W2T631117 | 6D-17750 | 6S-30629/2 | Check Valve DN25 JIS 10K |

| W2T631118 | 6D-17750 | 6S-30629/3 | Check Valve DN40 JIS 10K |

| W2T821953 | 6D-19949 | 6S-32995/1 | Diaphragm Valve DN15 ANSI 150 |

| W2T821954 | 6D-19949 | 6S-32995/2 | Diaphragm Valve DN25 ANSI 150 |

| W2T821955 | 6D-19949 | 6S-32995/3 | Diaphragm Valve DN40 ANSI 150 |

| W2T821957 | 6D-19949 | 6S-32995/5 | Diaphragm Valve DN15 EN1092 |

| W2T821958 | 6D-19949 | 6S-32995/6 | Diaphragm Valve DN25 EN1092 |

| W2T821959 | 6D-19949 | 6S-32995/7 | Diaphragm Valve DN40 EN1092 |

| W2T625176 | 4-21329 | 6S-13536/2 | Diaphragm Valve DN25 EN1092 |

| W2T625584 | 4-21329 | 6S-13536/3 | Diaphragm Valve DN40 EN1092 |

| W2T630811 | 6D-19757 | 6S-13939/1 | Diaphragm Valve DN25 JIS 10K |

| W2T630812 | 6D-19757 | 6S-13939/2 | Diaphragm Valve DN40 JIS 10K |

Send your inquiry to info@venteville.com