Bilge Water Treatment

The Seriousness of Bilge Water Management

Bilge water, generated in engine rooms, is linked to significant fines and imprisonment for improper handling. The term “magic pipe” is familiar to marine engineers, many of whom have witnessed it in use.Why the Issue Persists

We believe the problem doesn’t stem from ignorance or mistrust but from a lack of appropriate tools for daily operations. Ship operators face challenges managing the complex waste produced in engine rooms.Complexity of Engine Room Waste

This wastewater contains more than oil and water; it includes chemicals, sewage, rust, lubrication oil, and other contaminants. Anything entering the engine room can end up in this mix.The Challenge for Marine Engineers

Conventional static separators are designed to treat only oil and water. They struggle with the wide array of substances present in modern engine room waste. This complex mixture creates an ongoing challenge for marine engineers managing the disposal of contaminated fluids.

Marinfloc / Bilge Water Treatment / EGR Water Treatment / Wastewater Treatment & Monitoring

part no.

Efficient Flocculation for Bilge and EGR Bleed-Off Water

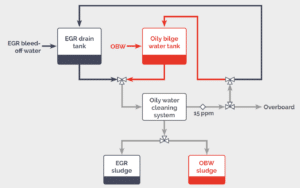

The CD EGR system offers a highly effective solution for cleaning both EGR and Bilge water using advanced flocculation technology. The combined EGR and Bilge Water Treatment system streamlines operations, reducing equipment, installation, operational costs, and the overall CO2 footprint. Despite the different MARPOL Annexes governing bilge water and EGR bleed-off water, the system ensures complete segregation, with separate holding and sludge tanks. System automation, including class-approved segregation valves, prevents any mixing of waste streams and sludge during treatment. From the control panel, operators can effortlessly select the waste stream for treatment, ensuring accurate discharge monitoring, record-keeping, and compliance with MARPOL standards through optional integration with the WhiteBox® system.

Process Overview

The CD unit can handle either EGR bleed-off or bilge water, depending on the selection from a control panel. Three three-way valves, connected to a selector switch, ensure these waste streams never mix. EGR bleed-off water is collected in a cascade-type drain tank, which includes heating coils to maintain a temperature of 40-55°C. Solid sensors in the tank detect soot solidification. Segregated sludge tanks are provided to meet MARPOL requirements. Once processed, wastewater is discharged overboard through a WhiteBox® system, which logs vital data such as tank levels, valve positions, oil content, and discharge volumes, ensuring seamless compliance and traceability.

By integrating bilge and EGR bleed-off water treatment, the CD EGR system ensures operational efficiency while maintaining environmental and regulatory compliance.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Key Features of Combined EGR and Bilge Water Treatment System

- Lower CAPEX as there is no need to procure a separate OWS.

- Lower OPEX, less documentation, classification cost and spare parts.

- Space-efficient with a smaller footprint.

- One high-end separator for two waste streams.

- Lower cost for commissioning.

Advantages of Marinfloc OWS system

- Flocculation technology. No cartridge filters nor centrifuges required.

- Adjustable to the ship specific EGR bleed-off water composition

- Low energy consumption for low carbon footprints

- Low operational cost

- Stainless steel material

- Made in Sweden

Applied regulations

- MEPC.307(73) regulated EGR bleed off water

- MEPC.107(49) regulated bilge water

Marinfloc / Bilge Water Treatment / EGR Water Treatment / Wastewater Treatment & Monitoring

part no.

OMD Recondition & Exchange Service

To maintain compliance with IMO Resolution MEPC.107(49) and ensure continuity, Marinfloc offers two cost-effective options for your OMD-24 – OMD-2005: Calibration and Exchange services.

Option 1 – OMD Cell Calibration

In this option, the client sends their OMD cell to Marinfloc. Once received, a Marinfloc-authorized engineer will calibrate the cell. After calibration, the OMD cell is returned within 14 days, ensuring minimal downtime and ongoing compliance.

Option 2 – OMD Exchange System

With the exchange option, Marinfloc sends a reconditioned and calibrated OMD cell from stock. Upon receiving the replacement, the client must return their old OMD cell within 60 days of the invoice. A credit will be issued once the old cell is returned.

Both options provide a reliable, efficient way to maintain your OMD unit’s performance while adhering to international regulations.

How to order

Download the pdf file to open the order form, select your options and send the form to info@venteville.com

Contact Us for More Information

If you have any questions.

CD 0.25 Unit: Advanced Bilge Water Treatment

The Oily Water Separator 0.25 System is a cutting-edge dissolved air flotation and flocculation unit designed to treat bilge water to below 5 ppm. This innovative technology allows operators to adjust the treatment dosage based on the current bilge water conditions. While it complies with MARPOL requirements, it was specifically developed to meet onboard ship conditions.

Key Benefits

The CD 0.25 unit offers several advantages:

- Flocculation Technology: This system eliminates the need for cartridge filters or centrifuges.

- Adaptability: It adjusts to the ship’s specific bilge water composition, ensuring effective treatment.

- Type Approved: The unit consistently achieves the required 5 ppm discharge limit.

- Low Energy Consumption: It helps maintain a low carbon footprint, promoting environmental sustainability.

- Integration Capability: The CD unit can seamlessly integrate with the Whitebox® system.

- Cost-Effectiveness: This system operates with low operational costs, enhancing overall efficiency.

Treatment Process

The treatment process consists of five stages: oil separation, aeration, flocculation, flotation, and filtration.

- Oil Separation: Free oil rises to the surface and separates from water in the oil descaler, transferring to the sludge tank by gravity.

- Aeration: Air dissolves into the water under pressure, enhancing the treatment process.

- Flocculation: Flocculation chemicals are added, which coagulate emulsions, chemicals, and particles into larger flocs.

- Flotation: The dissolved waste from the aeration process combines with flocs and rises to the top of the flotation tank and removed to the sludge tank.

- Filtration: Finally, the clean water from the flocculation process undergoes filtration to achieve a discharge limit of 0-5 ppm before release overboard.

The Oily Water Separator 0.25 CD unit has a maximum capacity of 0.25 m³ per hour, making it a reliable solution for efficient bilge water treatment on board.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Technical data:

- Capacity of treated Bilge Water: Max 250 litres/hour

- Operating temperature of Bilge Water Optimal: +55°C ,Max. +60°C, Min +40°C

- Operating pressure: 0,25-0,4 MPa(g) / 2,5-4 bar(g)

- Test pressure: 0,78 MPa(g) / 7,8 bar(g)

- Safety valve release (Filters, Oil desc, Circ tank): 0,60 MPa(g) / 6 bar(g)

- IP-class: IP 54

- Voltage supply: 3×400-440 Vac, 50-60 Hz

- Fuse: 10 A

- Electric Power Consumption: 1,6 kW

- General Service Air Pressure: 0.6-0.9 MPa(g) 6-9 bar(g)

- General Service Air Consumption: < 2 normal litres/second

- Total net weight inc. Filter media (dry): 460 kg

- Total operating weight: 670 kg

CD 1.0 Unit: Advanced Bilge Water Treatment

The Oily Water Separator 1.0 System is a cutting-edge dissolved air flotation and flocculation unit designed to treat bilge water to below 5 ppm. This innovative technology allows operators to adjust the treatment dosage based on the current bilge water conditions. While it complies with MARPOL requirements, it was specifically developed to meet onboard ship conditions.

Key Benefits

The CD 1.0 unit offers several advantages:

- Flocculation Technology: This system eliminates the need for cartridge filters or centrifuges.

- Adaptability: It adjusts to the ship’s specific bilge water composition, ensuring effective treatment.

- Type Approved: The unit consistently achieves the required 5 ppm discharge limit.

- Low Energy Consumption: It helps maintain a low carbon footprint, promoting environmental sustainability.

- Integration Capability: The CD unit can seamlessly integrate with the Whitebox® system.

- Cost-Effectiveness: This system operates with low operational costs, enhancing overall efficiency.

Treatment Process

The treatment process consists of five stages: oil separation, aeration, flocculation, flotation, and filtration.

- Oil Separation: Free oil rises to the surface and separates from water in the oil descaler, transferring to the sludge tank by gravity.

- Aeration: Air dissolves into the water under pressure, enhancing the treatment process.

- Flocculation: Flocculation chemicals are added, which coagulate emulsions, chemicals, and particles into larger flocs.

- Flotation: The dissolved waste from the aeration process combines with flocs and rises to the top of the flotation tank and removed to the sludge tank.

- Filtration: Finally, the clean water from the flocculation process undergoes filtration to achieve a discharge limit of 0-5 ppm before release overboard.

The Oily Water Separator 1.0 CD unit has a maximum capacity of 1 m³ per hour, making it a reliable solution for efficient bilge water treatment on board.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Technical data:

- Capacity of treated Bilge Water: Max 1000 litres/hour

- Operating temperature of Bilge Water Optimal: +55°C ,Max. +60°C, Min +40°C

- Operating pressure: 0,25-0,4 MPa(g) / 2,5-4 bar(g)

- Test pressure: 0,78 MPa(g) / 7,8 bar(g)

- Safety valve release (Filters, Oil desc, Circ tank): 0,60 MPa(g) / 6 bar(g)

- IP-class: IP 54

- Voltage supply: 3×400-440 Vac, 50-60 Hz

- Fuse: 10 A

- Electric Power Consumption: 2,3 kW

- General Service Air Pressure: 0.6-0.9 MPa(g) 6-9 bar(g)

- General Service Air Consumption: < 5 normal litres/second

- Total net weight inc. Filter media (dry): 890 kg

- Total operating weight: 1400 kg

CD 2.0 Unit: Advanced Bilge Water Treatment

The Oily Water Separator 2.0 System is a cutting-edge dissolved air flotation and flocculation unit designed to treat bilge water to below 5 ppm. This innovative technology allows operators to adjust the treatment dosage based on the current bilge water conditions. While it complies with MARPOL requirements, it was specifically developed to meet onboard ship conditions.

Key Benefits

The CD 2.0 unit offers several advantages:

- Flocculation Technology: This system eliminates the need for cartridge filters or centrifuges.

- Adaptability: It adjusts to the ship’s specific bilge water composition, ensuring effective treatment.

- Type Approved: The unit consistently achieves the required 5 ppm discharge limit.

- Low Energy Consumption: It helps maintain a low carbon footprint, promoting environmental sustainability.

- Integration Capability: The CD unit can seamlessly integrate with the Whitebox® system.

- Cost-Effectiveness: This system operates with low operational costs, enhancing overall efficiency.

Treatment Process

The treatment process consists of five stages: oil separation, aeration, flocculation, flotation, and filtration.

- Oil Separation: Free oil rises to the surface and separates from water in the oil descaler, transferring to the sludge tank by gravity.

- Aeration: Air dissolves into the water under pressure, enhancing the treatment process.

- Flocculation: Flocculation chemicals are added, which coagulate emulsions, chemicals, and particles into larger flocs.

- Flotation: The dissolved waste from the aeration process combines with flocs and rises to the top of the flotation tank and removed to the sludge tank.

- Filtration: Finally, the clean water from the flocculation process undergoes filtration to achieve a discharge limit of 0-5 ppm before release overboard.

The Oily Water Separator 2.0 CD unit has a maximum capacity of 2 m³ per hour, making it a reliable solution for efficient bilge water treatment on board.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Technical data:

- Capacity of treated Bilge Water: Max 2000 litres/hour

- Operating temperature of Bilge Water Optimal: +55°C ,Max. +60°C, Min +40°C

- Operating pressure: 0,25-0,4 MPa(g) / 2,5-4 bar(g)

- Test pressure: 0,78 MPa(g) / 7,8 bar(g)

- Safety valve release (Filters, Oil desc, Circ tank): 0,60 MPa(g) / 6 bar(g)

- IP-class: IP 54

- Voltage supply: 3×400-440 Vac, 50-60 Hz

- Fuse: 10 A

- Electric Power Consumption: 2,56 kW

- General Service Air Pressure: 0.6-0.9 MPa(g) 6-9 bar(g)

- General Service Air Consumption: < 9 normal litres/second

- Total net weight inc. Filter media (dry): 1110 kg

- Total operating weight: 2010 kg

CD 5.0 Unit: Advanced Bilge Water Treatment

The Oily Water Separator 5.0 System is a cutting-edge dissolved air flotation and flocculation unit designed to treat bilge water to below 5 ppm. This innovative technology allows operators to adjust the treatment dosage based on the current bilge water conditions. While it complies with MARPOL requirements, it was specifically developed to meet onboard ship conditions.

Key Benefits

The CD 5.0 unit offers several advantages:

- Flocculation Technology: This system eliminates the need for cartridge filters or centrifuges.

- Adaptability: It adjusts to the ship’s specific bilge water composition, ensuring effective treatment.

- Type Approved: The unit consistently achieves the required 5 ppm discharge limit.

- Low Energy Consumption: It helps maintain a low carbon footprint, promoting environmental sustainability.

- Integration Capability: The CD unit can seamlessly integrate with the Whitebox® system.

- Cost-Effectiveness: This system operates with low operational costs, enhancing overall efficiency.

Treatment Process

The treatment process consists of five stages: oil separation, aeration, flocculation, flotation, and filtration.

- Oil Separation: Free oil rises to the surface and separates from water in the oil descaler, transferring to the sludge tank by gravity.

- Aeration: Air dissolves into the water under pressure, enhancing the treatment process.

- Flocculation: Flocculation chemicals are added, which coagulate emulsions, chemicals, and particles into larger flocs.

- Flotation: The dissolved waste from the aeration process combines with flocs and rises to the top of the flotation tank and removed to the sludge tank.

- Filtration: Finally, the clean water from the flocculation process undergoes filtration to achieve a discharge limit of 0-5 ppm before release overboard.

The Oily Water Separator 5.0 CD unit has a maximum capacity of 5 m³ per hour, making it a reliable solution for efficient bilge water treatment on board.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Techincal data:

- Capacity of treated Bilge Water: Max 5000 litres/hour

- Operating temperature of Bilge Water Optimal: +55°C ,Max. +60°C, Min +40°C

- Operating pressure: 0,25-0,4 MPa(g) / 2,5-4 bar(g)

- Test pressure: 0,78 MPa(g) / 7,8 bar(g)

- Safety valve release (Filters, Oil desc, Circ tank): 0,60 MPa(g) / 6 bar(g)

- IP-class: IP 54

- Voltage supply: 3×400-440 Vac, 50-60 Hz

- Fuse: 10 A

- Electric Power Consumption: 4,3 kW

- General Service Air Pressure: 0.6-0.9 MPa(g) 6-9 bar(g)

- General Service Air Consumption: < 9 normal litres/second

- Total net weight inc. Filter media (dry): 1900 kg

- Total operating weight: 3750 kg

Marinfloc Whitebox: Overboard Discharge Monitoring

The Marinfloc Whitebox serves as a failsafe overboard discharge monitoring and control unit. Installed between the Oily Water Separator (OWS) and the overboard valve, it effectively prevents non-compliant discharge of bilge water. Additionally, the Whitebox protects the crew from accusations by presenting evidence of the vessel’s discharge activities. Not only does it log vital data, but it also actively helps prevent illegal discharge.

Comprehensive Data Monitoring

The Whitebox records all essential discharge data and links it to the vessel’s GPS. It houses all necessary monitoring and control equipment for overboard discharge. A digital recorder captures critical information such as oil content, valve settings, flow rates, door status, vessel position, and timestamps.

Moreover, the Whitebox can monitor the sewage overboard pump or Sewage Treatment Plant (STP) if connected. The system stores data in a secure digital format, allowing crews to present discharge data to the USCG, vetting agencies, classification societies, or port state authorities. This comprehensive data set enables detailed analyses for preventive and performance reports.

Furthermore, the OCEAN GUARDIAN® connects to the Whitebox, automatically closing the three-way valve when the vessel crosses the 12-nautical mile line. This feature enhances compliance with international regulations.

Additionally, the Whitebox can monitor discharge from clean drains, such as air conditioning systems or engine cooling drains. While this water is generally clean, it may still contain trace oil. Therefore, we recommend routing it through the Whitebox®. If oil is present, the system directs it to the bilge water tank for treatment by the OWS. This approach significantly reduces daily bilge water yield and lowers both operation time and running costs for the OWS. Overall, the Marinfloc Whitebox® provides a comprehensive solution for monitoring and controlling overboard discharge, ensuring compliance and enhancing operational efficiency.

Contact Us for More Information

If you have any questions or require spare parts for your Marinfloc system.

Technical data:

- Max capacity of flow rate: 20000 l/h

- Max surrounding temperature: 50°C (To be cooled by vent. system)

- Max water temperature *: 60°C

- Operating pressure: 0.25 – 0.40 MPa

- Electric power consumption: 75 W

- IP-class: IP54

- Voltage supply: 230 Vac, 50-60 Hz

- Fuse: 6 A

- General Service Air Pressure: 0.6-0.9 MPa

- Flanges: DIN, DN40, PN16

- Total weight: 105 Kg

- Size – Lenght,Width, Height: 950 x 350 x 740 mm